The integration that is revolutionizing the spray industry.

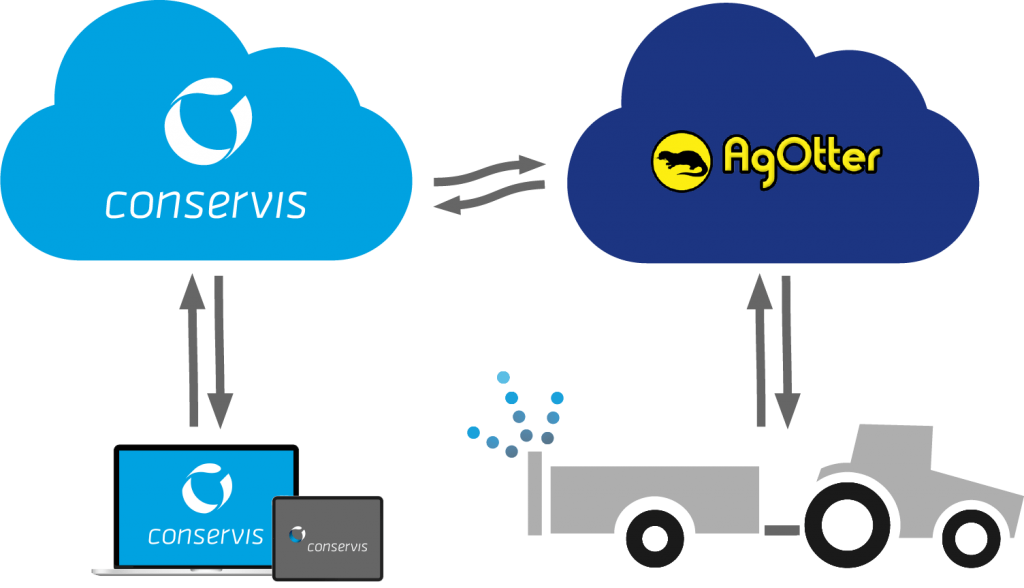

Conservis’ integration with AgOtter automates and simplifies the management of spraying activities, therefore saving time, improving control, and reducing costly mistakes.

- Automate entire spray process

- Improve efficiency and reduce mistakes

- Comply with regulations

- Automate inventory

No other system exists that can provide end-to-end control and automation of the spray

How it works

How does the AgOtter-Conservis integration support your spray process?

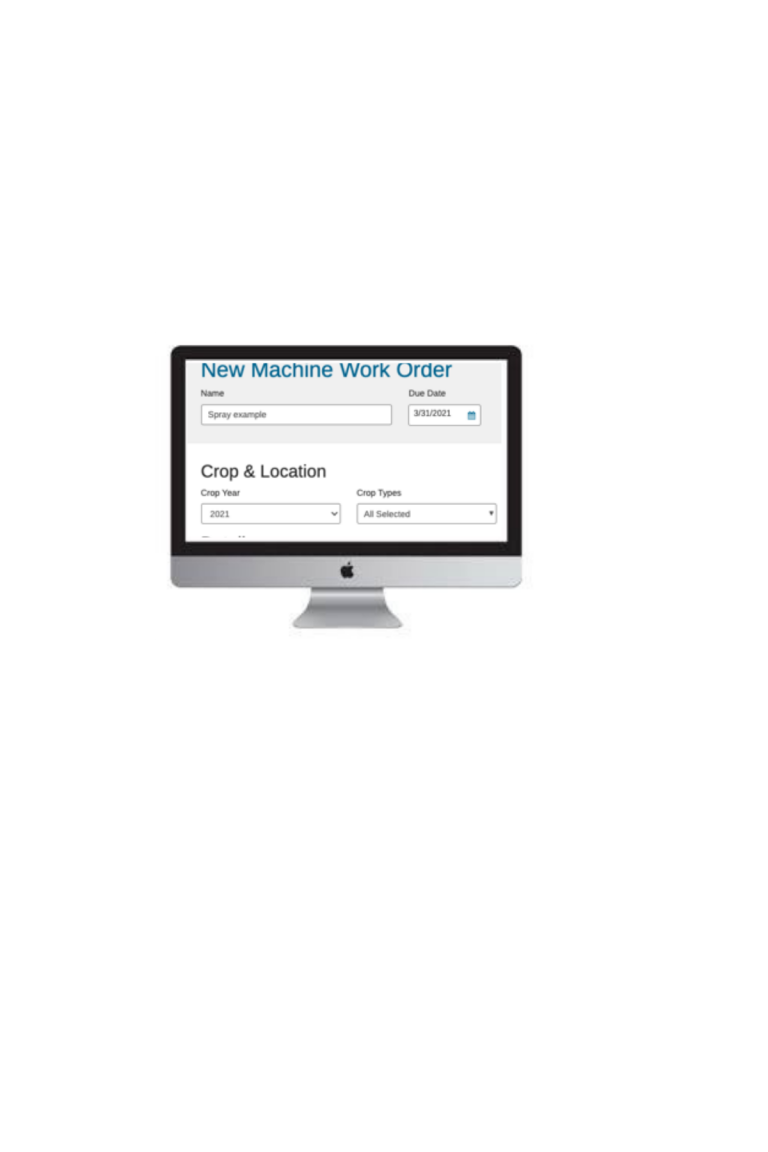

PLAN

Planning and Budgeting

- Wirelessly send planned jobs and work orders directly to the sprayer on the AgOtter app.

- Plan future AgOtter jobs and financial plans at the block level.

- Create whole farm, lender ready budgets.

- Budget and respond to changing conditions.

Purchasing and Inventory

- Create shopping lists of inputs and real-time purchase orders.

- Confirm needed inputs are onsite for planned AgOtter jobs.

- Manage Inventory knowing that you have the necessary inputs needed for the AgOtter application

Execute

Application

- Wirelessly recieve jobs that automatically populate the sprayer and the AgOtter Controller with row width and spray rate, reducing user touchpoints that can lead to costly errors.

- Start with a calibrated machine using AgOtter to ensure equipment is set correctly prior to entering the field.

- As the application occurs the AgOtter will actively calibrate the sprayer to ensure that the rate is on target throughout the entire application regardless of changing driver speeds.

Driver Awareness

- Driver can confirm uniform coverage on an AgOtter iPad in the cab to see independent flow rates for left and right boom.

- AgOtter will flag the driver with on-screen alerts for overspeed and imbalanced rate.

Track and Monitor

- As the application is being performed, the AgOtter automatically sends data to the cloud for real-time monitoring.

- Spray data is automatically sent to Conservis when the application is complete.

Verify

Real-time observation with AgHippo

- Manage spray team real-time in the field increasing operational efficacy.

- Oversee actual job data to verify that the sprayer is applying at the correct rate and speed for the job.

- AgHippo will send production report of the last 24 hours to your inbox every morning.

- Identify over/ under application trends to correct.

- Double or skipped rows will no longer be a mystery.

- Confirm that there was uniform coverage with left/ right boom comparison.

Analyze

Real-time observation with AgHippo

- Check driver idle times and fleet efficiency metrics.

- Find problematic sprayers and/or drivers.

- Know what has been done vs. the production plan and adjust as needed in a timely fashon.

Compare

- Manager budget to actual cost variances with high confidence.

- Know the cost and profitability by orchard, block, and variety.

- Identify most profitable practices to optimize and control costs.

- Compare performance and efficiency across blocks and cultural practices to drive operational efficiencies.

- Feed analysis back into the planning process to make future improvements.